Integrated RFID for Apparel at the Center of Recent Acquisition

Avery Dennison Smartrac intends to market UHF RFID products that can be sewn or built into garments to provide loss prevention and tracking functionality for a product’s entire lifespan.

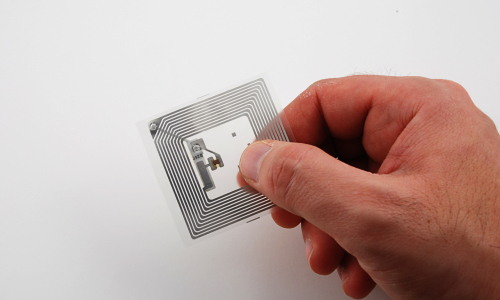

(Image: Albert Lozano-Nieto/stock.adobe.com)

As a growing number of retailers have adopted UHF RFID technology for inventory management, many are now looking for ways to further leverage the tags applied to their products, in order to gain more benefits and reduce costs. One area in which retailers have expressed interest is loss prevention, by which an RFID reader at a door could identify, via RFID tags, any goods removed from the store without being purchased.

With this use case in mind, among others, Avery Dennison Smartrac has acquired TexTrace, an integrated RFID products company, with a strategy to provide textile RFID labels that remain on garments for their entire lifetime, either in a sewn-on label or built into a product’s seam. By leveraging integrated RFID, the companies explain, retailers could accomplish loss prevention, since the tags cannot be easily removed.

Additionally, TexTrace and Avery Dennison anticipate future applications for RFID in the recycling of garments at the end of their lifetime, provided that the technology is integrated into those garments.

TexTrace was founded in Frick, Switzerland, more than a decade ago, with the goal of making custom-woven RFID labels for the fashion industry. The company has licensed its technology to apparel service bureaus, including Avery Dennison, which provides the inductive coupling antenna used for the integrated labels. The acquisition, announced Feb. 1, provides Avery Dennison with ownership of TexTrace’s portfolio of intellectual property. Avery Dennison says employees will continue to operate out of the Frick office.

One global retailer, which has asked to remain unnamed, is integrating TexTrace’s labels into its garments, while Avery Denison is in discussions with other potential customers. Additional development is planned to make the textile-based labels more robust for repeated washing. At present, the labels can withstand about four or five washing cycles, while the company predicts future versions could sustain hundreds of laundry cycles.

Avery Dennison expects to provide the TexTrace technology for use throughout a garment’s lifespan so that the tags could be read along the supply chain, in stores, and by waste-management companies when clothing is discarded, thereby ensuring the tags are properly recycled or reused.

During the past few years, says Mathieu De Backer, Avery Dennison Smartrac’s senior director of segment innovation, “We see more requirements for integrated technologies in the garment industry.” Part of the company’s vision, he says, is “a future where the digital will always be connected with the physical world, so every physical item will have a digital entity.”

The TexTrace acquisition, De Backer explains, is intended to further that effort. As more retailers already using RFID now seek ways to further leverage the technology, De Backer says, loss prevention comes to the forefront. Traditional electronic article surveillance (EAS) often involves a hard tag that must be applied to garments at the store and then be removed at the point of sale. The cost of the tags, he notes, as well as the labor involved in using them, can be relatively expensive and time-consuming.

By acquiring TexTrace, and by offering its technology as an alternative to paper-based hangtags, Avery Dennison intends to enable loss prevention for use cases in which EAS technology has been employed in the past.

EAS, De Backer explains, can trigger alarms without offering intelligence related to what is being removed, whereas RFID provides that intelligence. In order to use RFID for loss prevention, he says, companies need the technology to be integrated into garments. Otherwise, it’s too easy for individuals to rip off tags and walk out of a store with the garments, leaving the tags behind.

In addition to loss prevention, Avery Dennison reports, another benefit of integrated RFID is its ability to track the life of a garment. When clothing is discarded, it often ends up in a waste stream, such as at a recycling station where products are sorted according to their materials. If RFID functionality is built into each garment and the recycling provider interrogates its tag with an RFID reader, the company could capture data such as the materials built into the product (cotton or polyester, for example), so that it could be properly sorted for recycling or reuse.

Currently, recycled goods sorting is a manual process. Workers may be sitting in front of a pile of clothing, visually examining every label and determining which items are polyester and which are polyimide. “It’s all manual,” De Backer says. “If you could think about automating the sorting process with an RFID tag, I think that’s powerful.” Because the process would thus be more efficient, Avery Dennison predicts it will put more garments back into recycling so that the material does not enter a landfill.

“I think, as RFID becomes a more integrated part of the garment, you can also activate circularity within the apparel industry,” De Backer states. For instance, the company envisions the integrated RFID tags to be a benefit for garment renting or leasing, with customers acquiring clothing and then returning it to providers for reuse by others. To make such use cases possible, the company intends to continue engineering the chip to improve its robustness.

For manufacturers, De Backer says, the application of textile-based labels or the integration of RFID directly into garments, typically sewn into the seam, may not be significantly different then applying paper tags. While service bureaus currently offer RFID labels in the form of hangtags, they could now simply provide a soft label that could be sewn into garments during the manufacturing process. Integrated RFID also provides the possibility for future consumer interaction, the company notes, by linking supply chain transparency with reuse and recycling information to create a link between brands and consumers.

The technology works with dual-frequency tags that incorporate Near Field Communication or HF RFID at 13.56 Mhz. With regard to privacy concerns for UHF RFID, De Backer says, the retailer could enable the RFID chip to be switched into “protect mode.” At that point, the tag would not be detectable by an RFID reader until it was turned back on with a specific password—for example, if the garment to which it was attached were returned to the store or brought to a recycling center.

Such functionality would require industry-wide standardization, he says, so that the tags could be interrogated by multiple authorized parties throughout their lifespan. “We still need to work together with the industry to make that standardized,” he states, “so that everybody is using the same methodology.” According to De Backer, Avery Dennison could take the leadership role in that effort, since a standardized system for the lifespan tracking of a garment is in the company’s best interest.

Avery Dennison does not expect to see paper labels fully phased out for RFID apparel tagging, though over time, De Backer expects there will be more integrated RFID solutions. “It’s a process.” Integrated RFID is a relatively new technology, he notes, which may follow a similar trajectory to the adoption curve of RFID in paper hangtags for the retail industry. “We want to do the right thing for ourselves,” he says, “but also for our planet.”

This article first appeared in SSI sister publication RFID Journal where Claire Swedberg serves as Senior Editor.

If you enjoyed this article and want to receive more valuable industry content like this, click here to sign up for our FREE digital newsletters!

Security Is Our Business, Too

For professionals who recommend, buy and install all types of electronic security equipment, a free subscription to Commercial Integrator + Security Sales & Integration is like having a consultant on call. You’ll find an ideal balance of technology and business coverage, with installation tips and techniques for products and updates on how to add to your bottom line.

A FREE subscription to the top resource for security and integration industry will prove to be invaluable.